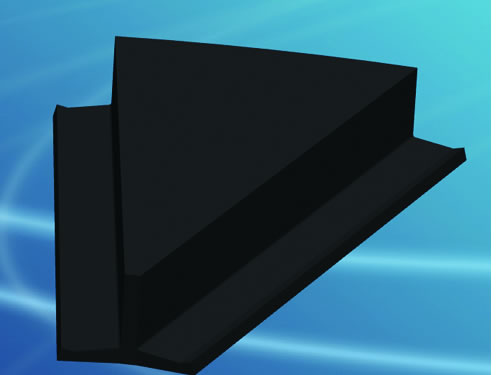

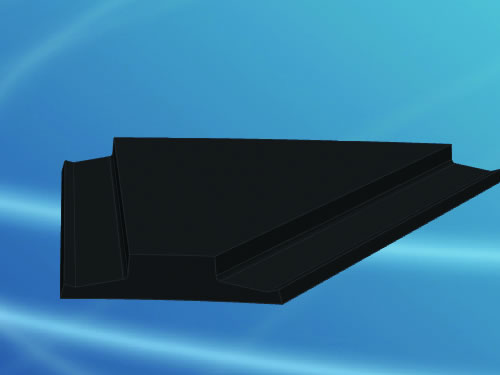

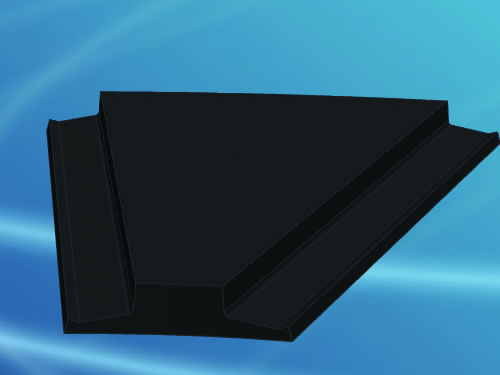

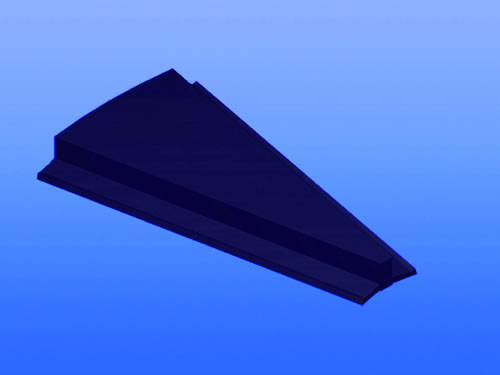

Ball Mill Head Liners

Description

The feed end liners for ball mill are an important part of conical ball mill. Its main function is to protect the end cover of ball mill. It is usually made of high manganese steel, chrome steel, wear-resistant cast iron or rubber material. The high wear-resistance head liner provided by us have improved the wear condition of the feed end liners for ball mill that make the end liners have good wear-resistance and effectively increase the service life. We can provide customized products according to client requirement.

Some Pictures of Head Liner

Types

Advantages

1. Our feed end liners for ball mill adapt to different grinding conditions with long lifespan.

2. It resistant to wear, hardening and corrosion, even the resistance up to 80°C.

3. This ball mill head plate operate safe with low operation noise.

4. Compared to metal ball mill head liners, the weight of this head liner reduction of up to 80%.

5. The installment of our production is easy, fast and safe, as well as fewer maintenance interruptions.

6. The feed end liners for ball mill reduce the liner costs per ton of material processed.

Specifications MM3

| Property | Units | Value |

| Hardness | Shore A | 62 |

| Tensile Strength | MPa | 20.5 ± 10 |

| Elongation at Break | 6.5 | ± 10 |

| Tear Strength | N/mm | 313 |

| Abrasion Loss | MM3 | 35 |

| Resilience | % | |

| Operating Temperatures (Continuous use) | -40℃to+70℃ | |

| Color | Black |

Remarks:

All physical property values developed and measured using a press-cured sample sheet prepared in accordance with GB/T18241.2-2000.

TallKee Rubber Products is equipped with strict quality control, testing procedures, and experienced engineers. We also have close cooperation with mineral processing industries and our rubber linings attain the best wear lifespan and grinding performances possible.

English

English Português

Português Русский

Русский