Home » Products

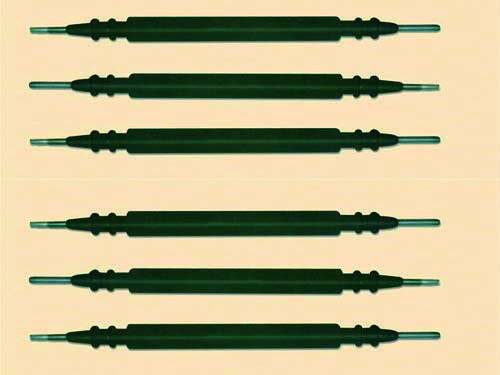

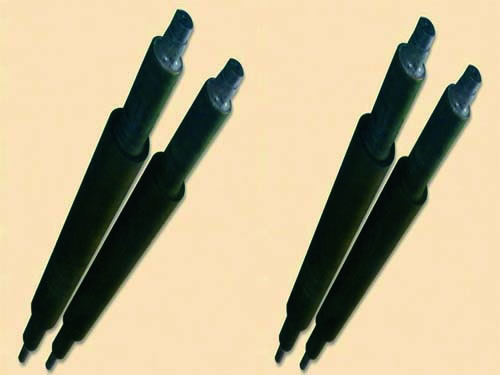

Heavy polyurethane rubber roller is made by covering a layer of elastic material of polyurethane around the metal roll core (ZG35 weight is around 1.5).

Heavy polyurethane rubber roller is made by covering a layer of elastic material of polyurethane around the metal roll core (ZG35 weight is around 1.5).

It is mainly used for the screening of coal mine, power station and coal preparation plants, and the final screening of over 13 mm particle size group and the pelletizing screening of steel enterprise pelletizing plants, as well as the screening of other block material.

It is mainly used for the screening of coal mine, power station and coal preparation plants, and the final screening of over 13 mm particle size group and the pelletizing screening of steel enterprise pelletizing plants, as well as the screening of other block material.

The performance of high temperature resistance of this product has been able to attain 280 degrees. All these rubber rollers offered by us can manufacture according to customers’ requirements.

The performance of high temperature resistance of this product has been able to attain 280 degrees. All these rubber rollers offered by us can manufacture according to customers’ requirements.

Outstanding elasticity and mechanical strength, resistant to abrasion, acid and alkali, oil, ageing and heat, long lifespan and fine performance.

Outstanding elasticity and mechanical strength, resistant to abrasion, acid and alkali, oil, ageing and heat, long lifespan and fine performance.

Outstanding elasticity and mechanical strength, resistant to abrasion, acid and alkali, oil, ageing and heat, long lifespan and fine performance.

Outstanding elasticity and mechanical strength, resistant to abrasion, acid and alkali, oil, ageing and heat, long lifespan and fine performance.

PU elastomer possesses good performance, such as resistant to abrasion, chemical erosion, high pressure load, radiation and tear, as well as high tensile strength, high elasticity, shock absorption, high strength, high bearing and shock mitigation.

PU elastomer possesses good performance, such as resistant to abrasion, chemical erosion, high pressure load, radiation and tear, as well as high tensile strength, high elasticity, shock absorption, high strength, high bearing and shock mitigation.

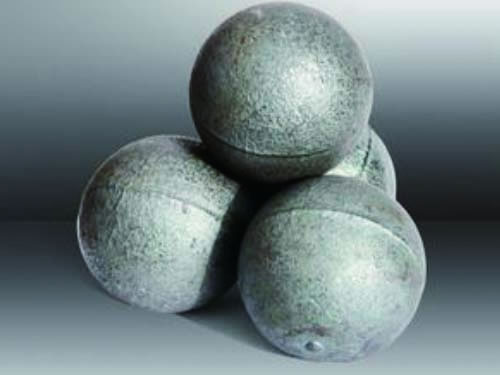

Forged steel ball is obtained by forging after direct high temperature heating. It’s named as forged steel ball because it’s only by tempering process, without melting and casting.

Forged steel ball is obtained by forging after direct high temperature heating. It’s named as forged steel ball because it’s only by tempering process, without melting and casting.

By different materials, the cast steel shot can be classified into four categories: cast iron ball, high chromium alloy casting ball, multielement alloy cast ball, and low chromium alloy cast ball.

By different materials, the cast steel shot can be classified into four categories: cast iron ball, high chromium alloy casting ball, multielement alloy cast ball, and low chromium alloy cast ball.

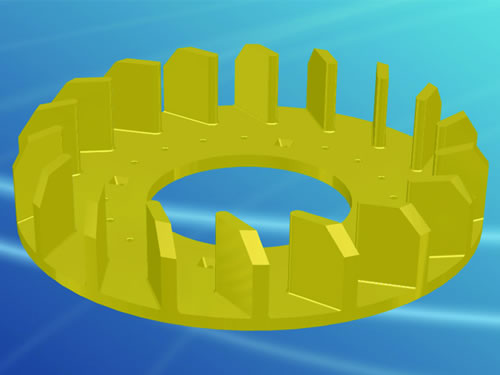

Rubber rotors and stators are the central components of flotation machine, which are mainly applied in beneficiation of metals or non-metals.

Rubber rotors and stators are the central components of flotation machine, which are mainly applied in beneficiation of metals or non-metals.

English

English Português

Português Русский

Русский